In today’s fast-paced digital world, businesses face the challenge of managing an overwhelming amount of data and processes. As operations grow more complex, companies need efficient solutions to streamline workflows, reduce costs, and boost productivity. This is where Enterprise Resource Planning (ERP) systems come into play. ERPs provide a centralized platform that integrates various business functions like finance, human resources, supply chain management, and more into one cohesive system.

While almost every industry can benefit from ERP systems, certain sectors experience more transformative results due to the nature of their operations. Let’s explore which industries need ERP systems the most and how they can benefit from this game-changing technology.

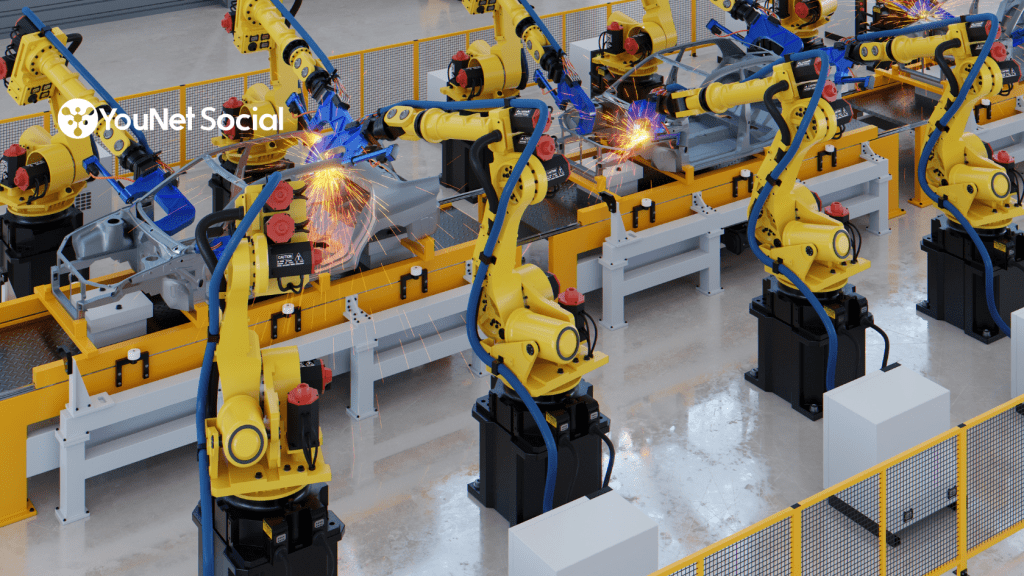

1. Manufacturing Industry

Manufacturing is a highly complex industry that requires the coordination of numerous processes—procurement, inventory management, production planning, shipping, and quality control. Any disruption or inefficiency in one area can create a ripple effect, leading to delays, increased costs, or compromised product quality. ERP systems play a pivotal role in addressing these challenges by providing an integrated platform that enhances operational efficiency across every phase of the manufacturing process.

- Managing Supply Chains

In manufacturing, supply chain management is critical to ensure the timely availability of raw materials and parts. ERP systems enable manufacturers to track raw materials in real-time, ensuring optimal inventory levels are maintained without overstocking or understocking. By monitoring supplier performance and automating reordering processes, manufacturers can minimize production delays and avoid costly stockouts. Furthermore, ERP systems offer insights into supplier reliability, lead times, and cost variances, helping manufacturers build stronger supplier relationships and negotiate better terms.

- Production Planning and Scheduling

Production planning is often a logistical challenge, especially in industries with fluctuating demand. ERP systems streamline production schedules by using historical data, demand forecasts, and real-time sales information to predict production needs accurately. This ensures that resources—whether labor, machinery, or materials—are allocated efficiently, reducing downtime and bottlenecks. Additionally, ERP systems provide real-time visibility into production progress, allowing manufacturers to adjust schedules dynamically based on current operational conditions. This agility helps manufacturers meet tight deadlines while minimizing waste and inefficiencies.

- Quality Control and Assurance

In today’s competitive market, maintaining product quality is non-negotiable. ERP systems provide a centralized platform for automating quality control processes at every stage of production. From monitoring raw material quality to tracking compliance with industry standards, ERP systems help ensure that quality is maintained consistently. Automated quality assurance workflows not only detect defects early but also enable root cause analysis, reducing the likelihood of reoccurring issues. By integrating quality control into the broader ERP framework, manufacturers can ensure products meet customer expectations while adhering to regulatory compliance and safety standards.

2. Retail and E-Commerce

The retail sector operates in an environment where rapid changes in consumer behavior, fluctuating demand, and complex supply chains can significantly impact business performance. Retailers must manage a delicate balance between inventory levels, customer satisfaction, and profitability. An ERP system becomes essential for retailers by offering comprehensive tools to streamline operations, respond to market changes, and enhance customer engagement.

- Automating Inventory Management

Inventory is at the heart of retail success, and improper stock management can lead to lost sales or excess holding costs. An ERP system allows retailers to track stock levels in real time, providing full visibility across warehouses and store locations. This ensures that stockouts and overstocking are minimized, improving efficiency in reordering processes. ERP systems use historical sales data and predictive analytics to automate inventory replenishment, preventing missed sales opportunities due to low stock while reducing unnecessary capital tied up in excess inventory. This automation also reduces manual errors, streamlines supply chain logistics, and enhances demand planning.

- Enhancing Customer Experience through Personalization

By integrating with CRM systems, ERP solutions enable retailers to offer highly personalized shopping experiences. Retailers can gather and analyze customer data—such as purchase history, preferences, and behavior patterns—to tailor marketing strategies, loyalty programs, and promotions. This data-driven personalization builds stronger customer relationships, leading to increased loyalty and repeat business. ERP systems further help in managing customer feedback and service interactions, ensuring seamless communication and prompt resolutions that contribute to positive shopping experiences.

- Managing Multi-Channel Retail Efficiently

With the rise of omnichannel retail, managing multiple sales channels—whether physical stores, e-commerce platforms, or mobile apps—has become more complex. An ERP system provides a unified platform to synchronize inventory and orders across all channels, ensuring customers have a consistent shopping experience whether they shop online or in-store. ERP systems streamline order fulfillment by enabling real-time updates on stock levels across various channels, preventing issues such as double-booking inventory or shipping delays. Additionally, ERP systems improve supply chain visibility, allowing retailers to efficiently allocate stock to the right channels based on demand, thereby reducing fulfillment times and improving customer satisfaction.

- Comprehensive Financial Management and Profit Optimization

Profit margins in the retail sector can be razor-thin, requiring precise control over pricing, promotions, and cost management. ERP systems provide advanced financial management tools that offer retailers greater insight into revenue streams, operational costs, and profit margins. Retailers can use ERP solutions to optimize pricing strategies based on real-time market conditions and customer demand, ensuring that promotions are profitable and pricing is competitive. ERP systems also enhance financial reporting and budgeting, helping retailers identify areas where cost-cutting measures or operational improvements can lead to higher profitability.

In the fast-paced and competitive world of retail, ERP systems act as the central nervous system for a retailer’s operations. By integrating inventory management, customer relationship management, omnichannel coordination, and financial control into one cohesive platform, ERP systems enable retailers to streamline processes and deliver exceptional customer experiences. With this comprehensive solution, retailers can remain agile and competitive, navigating market fluctuations and shifting consumer preferences while maximizing profitability.

The retail sector is highly dynamic, with fluctuating demand, complex logistics, and customer management. ERP systems can:

- Automate Inventory Management: Track stock in real time, prevent stockouts, and optimize reordering.

- Improve Customer Experience: Integrate with CRM systems to provide personalized shopping experiences.

- Efficiently Manage Multiple Channels: Synchronize inventory and orders across online and physical stores.

- Financial Management: Gain better control over pricing, promotions, and profit margins.

ERP systems allow retailers to remain competitive by offering seamless operations and enhanced customer experiences.

3. Construction and Engineering

Construction firms deal with multiple projects, budgets, and timelines that need careful coordination. ERP systems help by:

- Project Management: Oversee project timelines, resource allocation, and labor costs.

- Financial Planning: Track expenditures, generate accurate cost estimates, and manage project budgets.

- Procurement and Supply Chain: Manage materials, suppliers, and equipment needed for ongoing projects.

- Compliance Management: Ensure compliance with industry standards and safety regulations.

ERP systems allow construction companies to deliver projects on time and within budget while minimizing costly delays and errors.

4. Automotive Industry

The automotive sector is characterized by complex production processes, supply chains, and regulatory demands. ERP systems are essential for managing these challenges, offering streamlined control and visibility across operations.

- Inventory and Supply Chain Optimization

With thousands of parts and components involved in vehicle assembly, ERP systems provide real-time inventory tracking, optimize stock levels, and automate procurement, ensuring smooth production without delays or excess inventory.

- Production Planning and Efficiency

ERP systems help coordinate production lines, optimize schedules, and reduce bottlenecks, enabling manufacturers to meet tight deadlines and improve just-in-time manufacturing processes, enhancing overall efficiency.

- Quality Assurance and Compliance

Maintaining product quality is critical in the automotive sector. ERP systems integrate quality control, track metrics, and enable real-time corrections to avoid defects and costly recalls. They also help meet regulatory requirements by maintaining compliance records.

- Cost Control and Profitability

By providing insights into cost structures at each production stage, ERP systems help manufacturers identify inefficiencies, optimize resource allocation, and improve profitability. Real-time financial analytics support strategic decision-making and long-term growth.

5. Food and Beverage

The food and beverage industry faces unique challenges, including strict safety regulations, fluctuating consumer demand, and complex supply chains. ERP systems are crucial for optimizing these operations while ensuring compliance and efficiency.

- Supply Chain and Inventory Management

ERP systems provide real-time tracking of perishable inventory, ensuring that raw materials and finished products are stored, moved, and used before expiration. By optimizing stock levels and automating reordering, ERP helps reduce waste and prevent shortages, crucial in a fast-moving industry.

- Production Planning and Efficiency

In the food industry, production scheduling must account for batch production and varying demand. ERP systems streamline this process by coordinating production lines and ensuring raw materials are available, reducing downtime and improving overall efficiency.

- Quality Control and Regulatory Compliance

With strict health and safety standards, ERP systems are essential for tracking quality metrics throughout the production process. They help enforce compliance with food safety regulations by maintaining detailed records and automating inspections, ensuring consistent product quality.

- Cost Management and Profitability

ERP systems provide insights into the cost of ingredients, production, and distribution, allowing companies to identify inefficiencies and manage costs effectively. This helps businesses adjust pricing strategies, improve profit margins, and reduce waste.

With an ERP system, food and beverage companies can ensure compliance, manage inventory efficiently, and deliver high-quality products.

Conclusion

Industries that deal with complex operations, large volumes of data, and stringent regulations stand to benefit the most from ERP systems. Investing in the right ERP system is crucial for long-term success, as it helps businesses reduce operational costs, improve decision-making, and enhance overall productivity.

At YouNet Social, we specialize in delivering fully integrated ERP systems designed to align perfectly with your business requirements and ensure seamless operations. If you’re looking to scale your business with a tailored ERP solution, connect with our IT experts today for more information!